Chemical Resistant Kapton & Polyimide

for Printed Circuit Board (PCB) applications. Polyonics' THERMOGARD™

product line exceeds harsh environment requirements for use in electronics, electrical, automotive and aerospace.

High Temperature Aluminum Labels and Polyimide Tags:

This product line provides superior high temperature

label and tag solutions designed to withstand extreme

track and trace applications in the steel and aluminum industry.

Antistatic Label Materials for Printed Circuit Board (PCB)

and Component Labeling. Electrostatic Discharge (ESD) damage affects production yield, product reliability and profitability in the electronics market.

As electronic devices continue to get smaller,

complex,and require greater power, the risk of a fire event increases.

Polyonics' offers Labels are made from Flame Retardant and

Halogen Free Label Material that won't contribute to fuel for propagating fire.

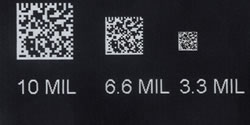

Due the lack of available space on PC Boards, labels have become smaller using very high density 2D bar codes. In addition,

the thickness of these labels can be an issue, especially if placed on components or parts within the body of the device.

Black and White Polyimide Materials are easily ablated

by a wide variety of lasers to provide longer term durability

and increased contrast and readability over traditional thermal transfer printed labels for high temperature

and harsh environment applications.

Polyonics' high temperature tags withstand

high temperatures encountered in many processes

and also exhibits tear resistance making them an ideal choice

for steel or any other hot material requiring a hang tag

(up to 600°C short term/ 350°C long term).

Polyonics offers Labels and Tags for Wire,

Wire Bundle & Cable Marking applications as well as

Polyimide markers that are used across many industries

from commuter railways to avionics. Polyonics' WIREGARD™ products are REACH, RoHS, PFOS, WEEE compliant.

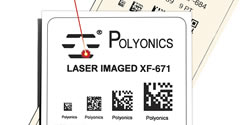

The Polyonics LML materials are designed to optimize

the direct part marking (DPM) by allowing manufacturers to

capture QC and test data by directly marking the labels in process.

Polyonics' LML materials use polyimide (PI) or PEEK films.